Please provide the following information: |

| 1. Bore diameter in mm/inches and quantity required |

| 2. Drawing to be provided by the customer |

| 3. Material to be extruded (PVC, PE, rubber, etc…) |

| 4. Material preferred in the tools (if not we will suggest the most suitable one) |

| |

| ※ In case of doubt, contact us for assistance in choosing the most suitable material for your extrusion tools. |

| ※ In case no tool drawing is available, send us a used wire guide or extrusion die. |

| ※ Please send your drawing for a quotation if you have any interest. |

|

According to customer needs in the choice of material selection

| (1)Special steel alloys |

| (2)Nitrided steel |

| (3)Hardened steel |

| (4)Alloy for fluoropolymer |

| (5)100%Tungsten carbide |

| (6)Steel with tungsten carbide insert |

| (7)Steel with diamond insert |

| (8)Steel with ceramic insert |

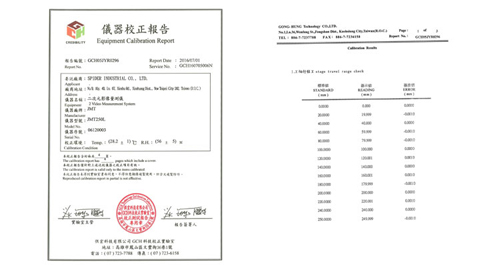

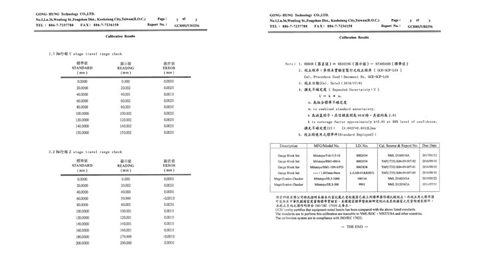

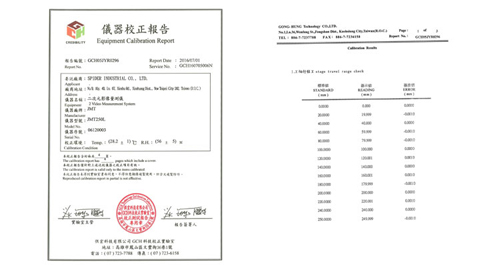

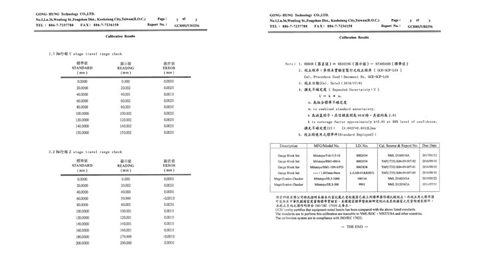

| 1. Accurate concentricity |

SPiDER is a worldwide leading manufacturer of Extrusion Tooling.

SPiDER can achieve is ±5μ(0.0002“)for O.D., I.D., concentricity, and roundness, etc. |

| 2. Shortest delivery |

| Our most precise machinery, coupled with the most specialized technicians and stringent quality control, ensures that our customers receive their finished products within the shortest time. |

| 3. High gloss polished Extrusion Tooling |

| Dies and Tips want to produce perform best, highly polished flow channels are the key. Extrusion tooling requires ground and lapped to a mirror finish, which will achieve better extrusion utility and better flow. |

| 4. Marking area |

| High definition laser marking the area with the diameter and other important customer details (upon client request). |

If you have any further questions, please contact us at any time. |

We do our best to respond to our customers immediately. |

It would be our pleasure to have long-term cooperation with you, thanks in advance! |